German Scientists have established an alloy with ultra-high-purity of magnesium of exceptionally low corrosion rate– Stainless Magnesium approach, via alloying of pure magnesium (Mg) with a tiny amounts of calcium (Ca) has been reported in Materials Horizons on 24th November 2020.

Mg is found to be the lightest structural metal with various properties like high strength-to-weight ratio, excellent electrochemical characteristics, Young’s modulus similar to human bone with low cost. Mg is widely used in aerospace, electronic, automotive, biomedical and energy-storage applications owing to its high strength, low weight, and excellent electrochemical properties, due to its abundance in the earth’s crust. Particularly, Mg possess light weight than aluminium (Al) and makes attractive from a sustainable perspective. Therefore, replacing of Al with ‘Stainless Mg’ in flights and cars will reduce the fuel consumption with free of carbon dioxide emissions. However, its usage is limited and restricted on an industrial scale, because Mg corrodes in aqueous environments. Over the last decades, the strengthening of the corrosion resistance is a main subject of intense research with respect to Mg investigation [1, 2].

Min Deng et al., have been reported for the first time that, on adding a tiny amounts of Ca to Mg will yield an exceptionally low corrosion rate (<0.1 mm y-1), making of ‘Stainless Mg’ possible in 3.5 wt% NaCl solution, which is found to be significantly lower than all other Mg alloys that have been reported elsewhere. The major break through is readily achieved via with cost-effective of conventional casting and metallurgical processing of (i) Formation of a protective surface film, (ii) Reduced cathodic water reduction kinetics, and (iii) Impurities stabilizing related to Ca micro-alloying [1, 2].

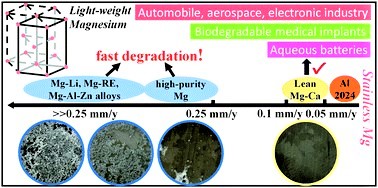

Figure 1. Newly developed Mg-Ca alloy [2].

Ca micro-alloying is been prepared via pure Mg and pure Ca was melted at high temperatures inside a steel crucible. Further, the melt is poured in to the steel mould. On using a tiny amounts of Ca, the new alloy will retains its properties of pure Mg. Afterwards, on cooling to room temperature, the new alloys are ready for use. But, this new alloy can resist corrosion, because the Ca reduces with the cathodic water which allows for the protective surface film development and also stabilize the impurities (such as Fe and Si) within the alloy. Eventually, the minor incorporation of Ca will imparts possibly a considerable influence on the surface film and the film thickness. It can also be revealed that the alloying of Ca on its low content can able to improve the high-temperature oxidation resistance of all Mg alloys [1, 2].

Figure 2. Various applications chart of newly developed Mg alloys [1].

To get hold back from corrosion of Mg, the most common way is the coating or alloying of Mg with various elements like Li, Al, As. On comparison to the existing alloying compositions, further addition of Ca will broadens to the practical applications for bio-implant material of Mg alloys, because Ca is found to be harmless to the human body when compared to other elements. It can also be found that, the addition of minor amounts of Arsenic (As) can lead to the poisoning at the cathodic reaction of Mg corrosion. Hence, this resulted to the restricted kinetics at the cathodic water reduction and will significantly enhance the corrosion resistance. Due to toxicity, the alternative group 14 and 15 elements like Bi, Ge, Sb and Sn will have a similar restriction effect on cathodic kinetics as proposed [2].

Nevertheless, to make an assumption that, the formation of MgO film on the Mg–Ca surface in aqueous media during corrosion can be reinforced with the incorporation of Ca. Besides, the calcium carbonate formation was involved during the film formation which can be taken into account for the carbonated electrolyte may be due to CO2 dissolved from ambient air. However, the formation mechanism and kinetics on the surface of the film composition on Mg–Ca alloys are still required of more research studies with mechanism aspects and other experimental characterization techniques [1].

‘Previous attempts to develop high corrosion-resistant magnesium alloys have always involved delicate and complicated processes, On comparison, the processing route for the Mg–Ca alloy with its superior performance is quite simple, eco-efficient and economical’– Linqian Wang.

‘The alloy could have biomedical applications, such as scaffolds and implants, because it seems to reduce significantly the formation of hydrogen bubbles, which are common in existing magnesium implant materials, and the formed corrosion products are not expected to be toxic’– Polina Volovitch.

Our SNB team have mainly emphasize this new research article to enrich our viewer’s knowledge about the new concept of simplifying the Mg-alloy composition that open up a fascinating research topic of highly developed corrosion-resistant Mg–Ca alloys. Further they reported that, Mg–Ca alloys with Ca contents of 0.05, 0.1 and 0.15 wt% has showed a remarkably lower corrosion rates (<0.1 mm y-1) in 3.5 wt% NaCl solution which paving a new way approach of ‘Stainless Mg’. Also the micro-alloyed Mg–Ca have retarded the reaction at cathode kinetics with the protective film formation of exceptional corrosion resistance. Corrosion-inducing impurities (like Fe and Si) will not impose any significant detrimental effect to the corrosion resistance of Mg–Ca alloys. Hence, this can be attributed to the Ca-induced stabilizing of impurities which results to a high microstructure homogeneity with a solid correlation between Mg–Ca alloy composition of excellent anti-corrosion property. Mg–Ca alloys with a huge potential of engineering materials can be used in transportation industry, particularly as biodegradable materials for medical implants and also as anode materials for aqueous Mg batteries. Practical applications of ‘Stainless Mg’ can certainly portable to electronics that come to mind, but as a wonder material (by Nick Birbilis), the world is magnesium’s oyster, ‘Steel came before skyscrapers, so let’s see what Mg will bring us in the near future.’

References

- M. Deng et al., Mater. Horiz., 8, 589 (2021), DOI: 10.1039/d0mh01380c.

- https://www.chemistryworld.com/news/new-magnesium-alloy-shows-exceptional-corrosion-resistance/4013323.article.

Dr. Y. Sasikumar

Comments

Post a Comment